Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

The change in production in the United States would therefore require years if not decades of coordinated investment in automation, tools, infrastructures and training. Encourage manufacturers of foreign components to build facilities in the United States would also be a challenge.

“If you are a Chinese supplier who makes a type of component that can also be used on a Huawei telephone or a xiaomi, you have levers,” says Mohan. “The incentive to separate these factories is low because you get scale and efficiency in China that you would not get if Apple was your only supplier.”

The uncertainty of politics is another problem, according to Tsay. “The American system as it is located, where everything can flow completely every four years, is not conducive to business investment. When people and companies make investments, they must have a longer horizon than that.”

Mark Randall was a Senior Vice President at Motorola when he was owned by Google and sought to build his North -Americans’ smartphone factory. The idea was not impossible, he says, but “he only knew it would be incredibly hard.”

The labor costs of the United States needed to transform raw materials into finished goods are “significantly higher” than elsewhere, according to him. The United States, for example, has a shortage of mechanical tool engineers. For a massive electronics manufacturing change in the United States, “we are talking about tens of thousands of them.”

The rates create a “nightmare” when modeling the costs of a new plant, adds Randall. “That is why most companies do not do short -term reactions and knees to the type of changes we are seeing today. You have to be super strategic and know where you are going in the long term.”

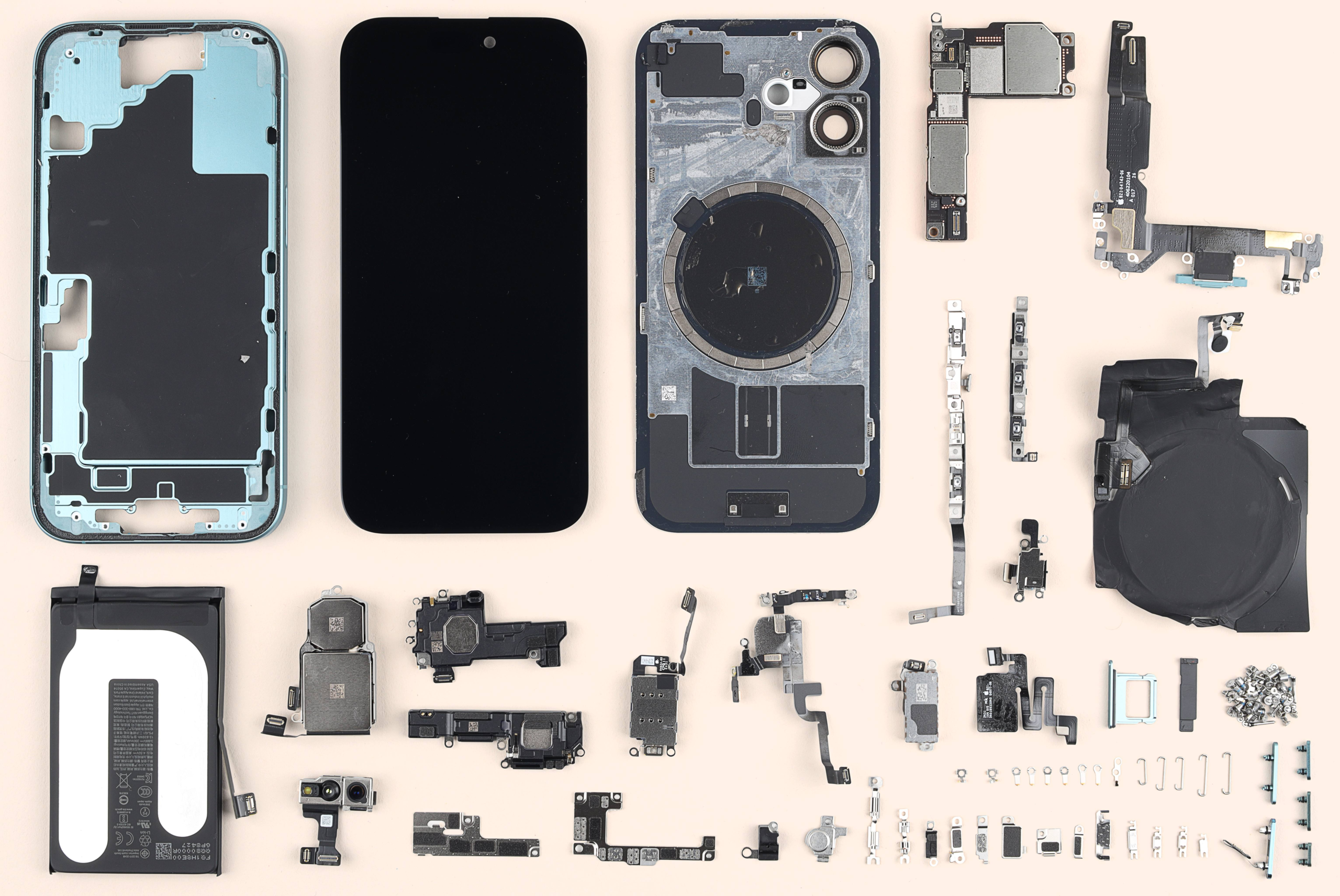

A deeper look into it supply chain for three parts in it ultimate iPhone models illustrated it complexities of moved manufacture into it Us, in a industry this need years into do even incremental Changes.

The only component of the touch screen that is currently made in America is the cover, produced by the long -haul glass maker from Apple to Kentucky, although the company also has facilities in China and India.

But the OLED screen that helps preserve the duration of the battery and an integrated multi-touch layer that allows the interaction on the screen is mainly by Samsung to South Korea.

The basic electronic parts that make the screen work combined with the visualization unit in the production facilities in China, before this component is transported to a Foxconn plant that combines with the rest of the the iPhone.

It metal skeleton pure capture it challenge of eliminate China since Apple supply chain. For more models, it cholera is slice and education since a block of aluminum use High accuracy computer numerical check (CNC) machines.

Wayne Lam, Techinsights analyst, says the process is based on an “army” of these machines, that Apple vendors in China have spent years accumulating and that they cannot be reproduced elsewhere. “If Apple was on the production of the iPhone on the floor, there would be not enough CNC machines that they can buy to satisfy the scale of the China Ecosystem,” He says.

LAm adds: “This is a specialized skill that is impossible to replicate outside China.”

Even it iPhone’s simpler component – is in miniature screws – are Complex. Them are liveststock since different material dependent over their paper, and have a number of CAP: Philips, plan, flat Tri-pip and Pentalobe, between others.

But it is the process that summarizes the challenges that the company would face if the iphone production was moved to the United States. Apple’s design, different from many other smartphone brands, does not use frame’s glue and analysts say that it is currently more profitable for Foxconn to hire people to make the screw to invest in robotic solutions.